Surface Analytics

Light Microscopy

Light-optical microscopy is usually the starting point for surface analysis. Using a stereomicroscope and various powerful digital light microscopes, we can quickly obtain an overview of the sample, document details and define areas to be examined for further methods such as SEM/EDX, XPS or FTIR.

Dimensions can be measured quickly and reliably thanks to software support with a resolution of down to 0.5 µm. Motorization of the Z-axis enables three-dimensional measurements of samples. It can also be used to automatically evaluate particle filters for technical cleanliness testing (TecSa).

Element analyses at specific positions can be carried out directly during microscopy using laser-induced plasma spectroscopy (LIPS or LIBS - Laser Induced Breakdown Spectroscopy). In multi-layered systems, depth profiles can be created through several layers by repeated positioning on a measuring point.

Facts:

- Magnification: up to 1000x / resolution up to approx. 0.5 µm

- Modes: bright field, dark field, polarization, differential interference contrast (DIC), fluorescence

- Microstructure, grain size and layer thickness analyses after cross-sectioning

- Profile measurements and dimensional measurements in 2D and 3D

- Roughness measurements

- Measurement of particle numbers and sizes

- Elemental analysis using LIBS

Contact person: Ursula Malang, Max Bruder

Electron microscopy (SEM) with energy dispersive X-ray spectroscopy (EDX)

Where the resolution of the light microscope is no longer sufficient, the scanning electron microscope (SEM) is usually used for surface analysis. In this method, the sample is scanned with an electron beam. The backscattered electrons and secondary electrons are then detected and used for imaging. Depending on the sample, a magnification of up to 100,000 times is possible.

For material analysis, electron microscopy is combined with energy dispersive X-ray spectroscopy (EDX). This allows the elemental composition of the sample to be determined non-destructively and with high spatial resolution.

Fakten:

- Magnification up to 100,000x

- Thermal field emission cathode (FE-SEM)

- Electron energy: < 1 keV - 30 keV

- Variable chamber pressure: UHV - 40 Pa

- Secondary electrons (SE) and backscattered electrons (BSE) detector

- Qualitative and quantitative element analysis including elemental mapping

- Information depth: approx. 0.1 to 1 µm

Contact person: Ursula Malang, Max Bruder

Photoelectron spectroscopy (XPS/ESCA)

X-ray Photoelectron Spectroscopy (XPS), sometimes also referred to as Electron Spectroscopy for Chemical Analysis (ESCA), is used to analyze the binding energy of electrons on the surface. This method is very suitable for analyzing the smallest impurities in the range of a few or even single atomic monolayers. It is therefore used to analyze bond surfaces or ultra-thin coatings, for example. The typical information depth ranges from atomic monolayers to approx. 10 nm, the spot area is typically between 300 µm x 700 µm and 55 µm x 55 µm, but can be reduced even further.

The bonding states and composition of the individual elements can be determined by high resolution measurements.

Imaging (local distribution of an element) and mapping (image of the spatially resolved composition) are available for spatial resolution. For depth profiling, the surface can be ablated using argon ion sputtering.

Facts:

- Depth profiling in nm steps

- Measuring spot size: 15 - 700 µm

- Typical information depth: 1 Angstrom up to 10 nm

Contact persons: Ursula Malang, Susi Reutz

Fourier transform infrared spectroscopy (FTIR)

Fourier transform infrared spectroscopy (FTIR) can be used to obtain information to identify organic materials. Special micro-techniques can also be used to examine particles, fibers, surfaces and thin layers.

Facts:

- Minimum layer thickness: 100 nm

- Minimum spot size: 100 µm

Contact: Susi Reutz

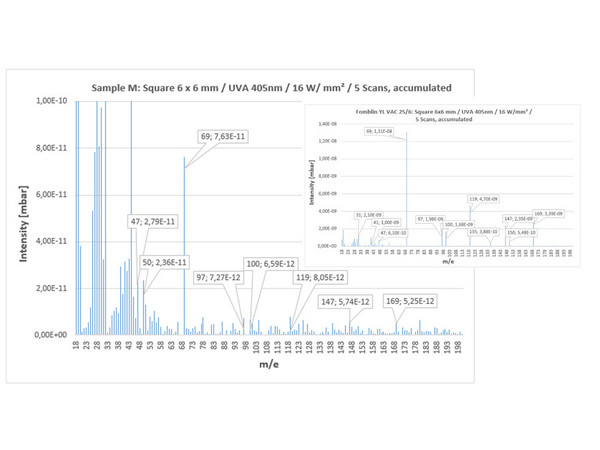

Laser-Induced desorption Mass Spectrometry (LIMS / LDMS)

In laser-induced desorption mass spectrometry - or laser desorption mass spectrometry - the sample or sample surface is locally thermally treated using a UV, VIS or IR laser - or directly ionized using a laser-induced microplasma. The laser beam can be applied selectively - or scanned over a defined area and thus applied directly to the sample surface.

Depending on the laser source, molecules or elements are thermally desorbed - or partially ionized - from the surface of the material at preselectable temperatures. With gentle thermal desorption in an ultra-high vacuum (UHV), only very little decomposition of the starting substances takes place, so that molecular ions (molecule peaks) are always in the foreground. Electronic post-ionization results in conventional 70 eV mass spectra, which can be evaluated using the usual MS libraries (NIST, Wiley). However, there are also cases in which IR or UV lasers cannot directly and gently desorb higher molecular substances, for example. For this purpose, special auxiliary substances (matrices) can be used in which the samples to be examined are embedded. These "matrices" absorb the laser energy very well and transfer it to the sample. This technique is known as "matrix-assisted laser desorption ionization" or MALDI. Ultra-fast time-of-flight mass spectrometers (TOF-MS) are usually used to detect the desorption products.

Contact person: Hans-Dieter Schmidt